SEM Lab, Inc. provides failure analysis and scanning electron microscopy (SEM) services to many branches of manufacturing, such as the electronics, medical, and aerospace industries, where these are vital tools used to determine the root cause of failures in order to keep them from recurring.

SEM Lab, Inc. has expertise which covers metals, ceramics, polymers, composites, and many more. Our failure analysis lab has performed thousands of root cause analyses and has experience with a wide range of failure modes, materials and processes. We would be happy to discuss your issue to determine a plan of action.

We have provided many examples of our failure analysis and SEM work as well as an on-going current blog showing some of our most interesting cases.

Failure Analysis

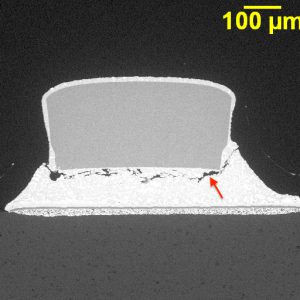

Metallurgical analysis

Corrosion problems

Structural failure analysis

Fracture analysis

Materials Analysis

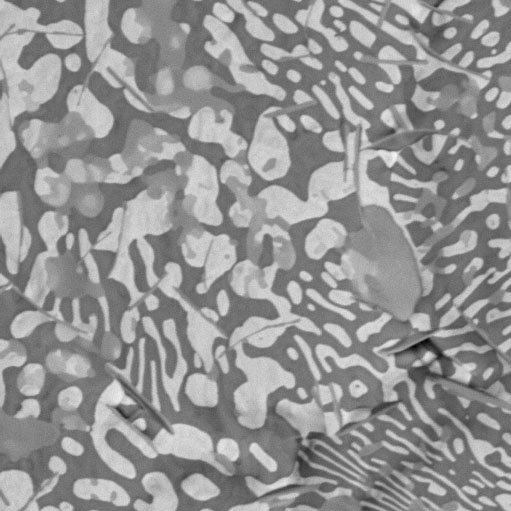

Characterization of materials (metals, plastics, ceramics, glasses)

FTIR (Fourier Transform Infrared Spectroscopy)

Particle analysis and identification

Metallurgical evaluation

Microstructural characterization

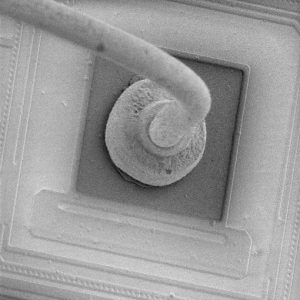

Electronic Component F/A

Device and component failures

Electronic assembly analysis

Component failure mechanisms

PWB construction analysis

Failure Analysis

SEM Lab, Inc. is a failure analysis lab providing services to many branches of manufacturing, such as the electronics, medical or aerospace industries, where it is vital to determine the root cause of a failure in order to keep it from recurring. At SEM Lab, Inc., we provide:

- F/A of Electronic Devices

- F/A of Medical Devices

- F/A of Ceramics and Plastics

- Metallurgical F/A

Materials Analysis

SEM Lab, Inc. performs materials analysis, identification, and characterization of a wide variety of materials and processes. Materials such as metals, plastics, ceramics, glasses, and particles are commonly examined.

- General Materials Analysis

- Electronic Materials and Process Analysis

Electronic Component F/A

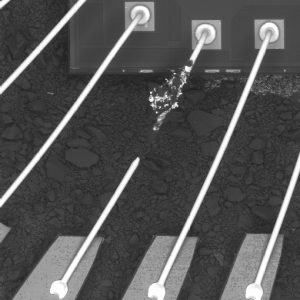

SEM Lab, Inc. is a lab that specializes in root cause failure analysis of electronic assemblies, printed-circuit-boards (PCBs), printed-wiring-boards (PWBs), and electronic components such as integrated circuits (ICs), transistors, diodes, capacitors, resistors, LEDs, power modules, and many others. We have analyzed electronic devices, components and assemblies for ESD, EOS, shorts, opens, corrosion, solderability, vibration, thermal fatigue, connector failures, etc.

Failure Analysis Lab

SEM Lab, Inc. provides failure analysis, materials characterization, scanning electron microscopy (SEM) and FTIR services. We specialize in root cause failure analysis of electronic assemblies, printed-circuit-boards (PCBs) or printed-wiring-boards (PWBs), and electronic components such as integrated circuits (ICs), transistors, diodes, capacitors, resistors, light emitting diodes (LEDs), power modules, and many others.

Since 1997 we have developed relationships with over 450 client companies including many of the most prominent electronic, medical and high technology companies in the world. And while SEM Lab, Inc. supports many large manufacturers, we also support small and medium sized manufacturers that may not have capabilities internally to perform failure analysis and materials characterization. We draw on over three decades of failure analysis and materials characterization experience with an emphasis on electronic materials and processes, electronic components, printed wiring boards, printed wiring assemblies, and more. We perform root cause failure analysis and can provide suggestions for corrective actions based on analysis results and past experience with the same issue.