These are some representative solder joint failure modes found in this laboratory that illustrate

* mechanical overload at high strain rate,

* thermal fatigue accelerated by gold embrittlement,

* creep rupture failure

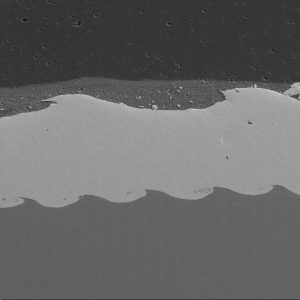

Example 1: This is an SMT thick film resistor solder joint. The solder joint failed in a brittle fracture mode at the interface between the solder and the nickel barrier plating (i.e. brittle interfacial fracture). The analysis results suggested that the resistor failure was most likely caused by mechanical stress (likely in bending) at a high strain rate.

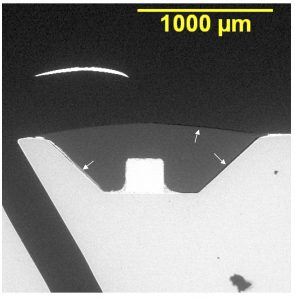

Example 2: This example shows a thermal fatigue fracture. The solder alloy is SN63, the package is a J-lead PMIC, and it is soldered to an alumina substrate. The thermal fatigue fracture showed classic characteristics such as grain boundary separation and propagation through the bulk solder joint. In this case, the failure was accelerated by gold embrittlement of the solder joint (bulk solder joint contained ~ 3 wt% of gold). Fracture is driven by cyclic creep-fatigue damage due to elastic displacement of the leads being converted to time-dependent plastic (creep) strain in the solder joint during thermal cycling. The cyclic strain is due to CTE mismatch between the PMIC and the ceramic substrate.

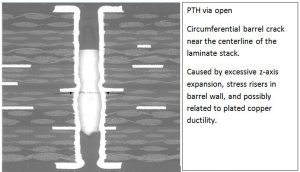

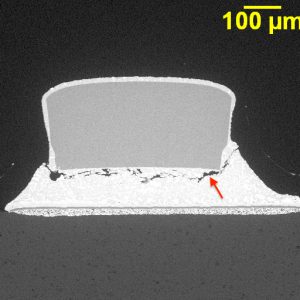

Example 3: This example shows a creep rupture failure of an SMT connector solder joint. The lead that failed was under stress as-soldered. The vertical displacement of the lead after the solder joint fractured is the key feature that suggests this was a creep rupture failure. The elastic strain of the lead is converted to creep strain in the solder joint until it either ruptures or the stress is relieved.

It is important to identify the failure mode accurately in order to formulate appropriate corrective actions.