Failure Analysis of Metals, Ceramics and Plastics

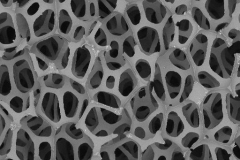

SEM Lab, Inc. is a failure analysis lab providing services to many branches of manufacturing, such as the electronics, medical or aerospace industries, where analysis is a vital tool used to determine the root cause of a failure in order to keep it from recurring. The process of failure analysis involves examining a failed component or part using various techniques and comparing with a non-failed part or drawing. First steps in root cause failure analysis may use non-destructive test methods. Subsequent testing would most likely employ cross-sectioning, and other destructive techniques to provide accurate root cause failure analysis.

SEM Lab, Inc provides failure analysis of metals, ceramics and plastics.

Failure Analysis of Metals, Ceramics, and Plastics

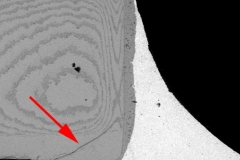

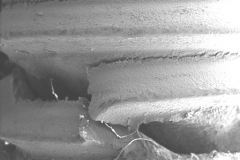

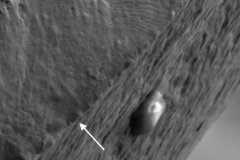

Fractures

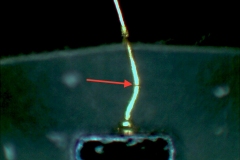

Examining the fracture surface of a failed part can provide important information regarding the failure mechanism. At our failure analysis lab we use SEM imaging and optical microscopy to classify the type of failure as ductile or brittle, for example. It can also yield information about the cause of the fracture such as corrosion, fatigue, etc.

Failure Analysis of Electronic Components

ICs, LEDs, PWBs, PCBs, Transistors, Inductors, Resistors, Capacitors, Components and Assemblies

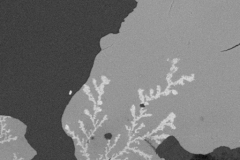

SEM Lab, Inc. is a failure analysis lab that provides analyses of integrated circuits (ICs), light emitting diodes (LEDs), printed wiring boards (PWBs), printed circuit boards (PCBs), transistors, inductors, resistors, capacitors, components and assemblies. We also provide analysis of medical devices. For a more detailed description of our electronic component failure analysis service, click on the link below.