Analyzing the Microstructure of Solder

Solder joint analysis is an important factor in determining the reliability of electronic assemblies. Solder joint defects can contribute to thermal, mechanical and electrical variations in devices and assemblies. SEM Lab, Inc. has extensive experience in solder joint metallurgical, quality and reliability analysis.

Modeling BGA Solder Joint Distortion

Caused by Warpage

This video illustrates how corner balls on BGA packages tend to elongate into hourglass shapes during reflow soldering.

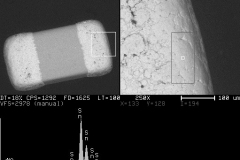

BGA Assembly Verification

Avoiding Failure During Production

SEM Lab, Inc. provides a comprehensive approach to BGA assembly validation using microsection and SEM analysis. The results can be used to optimize assembly processes early in the product development cycle and help to prevent failure during production.

The presentation below describes this process:

Solder Joint Reliability Analysis

Microstructural Characterization and Evaluation

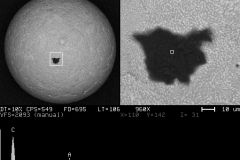

SEM Lab, Inc. does detailed root cause analysis of solder joint failures which includes gold embrittlement, thermal and vibration fatigue, tin whiskers, electromigration, corrosion, intermetallic compounds, head-in-pillow defect, and black-pad-syndrome.

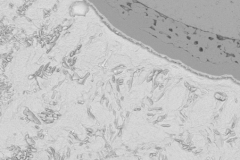

Solder Composition Analysis

Percentage of Lead

The amount of lead (Pb) in solder joints can affect reliability. Lead-tin (Pb-Sn) surface finishes on electronics components should have a minimum of 3% Pb to avoid tin whiskers, but often lead-free solder is employed. SEM Lab, Inc. uses SEM/EDS data from Sn-Pb standards to verify the solder composition.